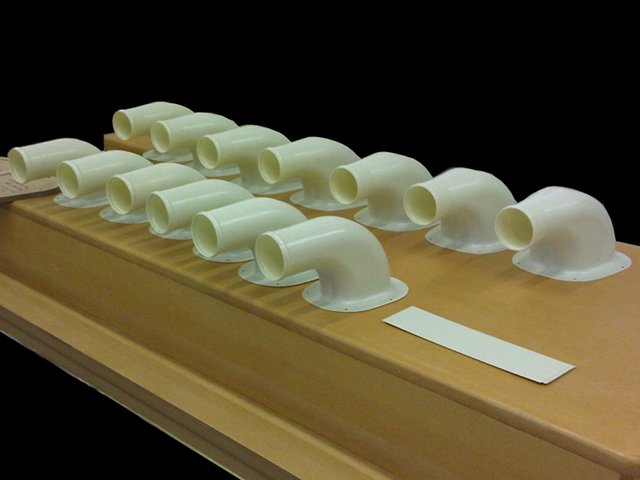

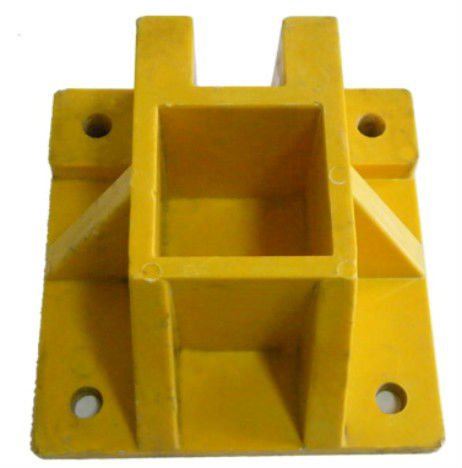

composite products

The typical composite materials can be made with fibers such as fiberglass, carbon fiber (graphite), Kevlar, quartz and polyester. The fibers come in veil mat, short fibers mat, woven cloth, unidirectional tape, biaxial cloth or triaxial cloth. The resins are typically thermal set resins such as polyester, vinyl ester, epoxy, polyurethane and phenolic. The resins start as a liquid and polymerize during the cure process and harden. The weight ratio of fibers to resin can range from 20% fibers to 80% resin to 70% fibers to 30% resin. Typically the higher fiber content provides even better strength and stiffness, and continuous fibers provide better strength and stiffness. The use of composite materials provides engineers the ability to tailor the combination of fibers and resin to meet design requirement, and perform better than standard materials.

Composites materials are replacing metals and plastics in many industries and composites are the material of choice for many new applications. Please see table 1 for a comparison of cost and properties of commercial grade composite materials to aluminum, steel and wood.